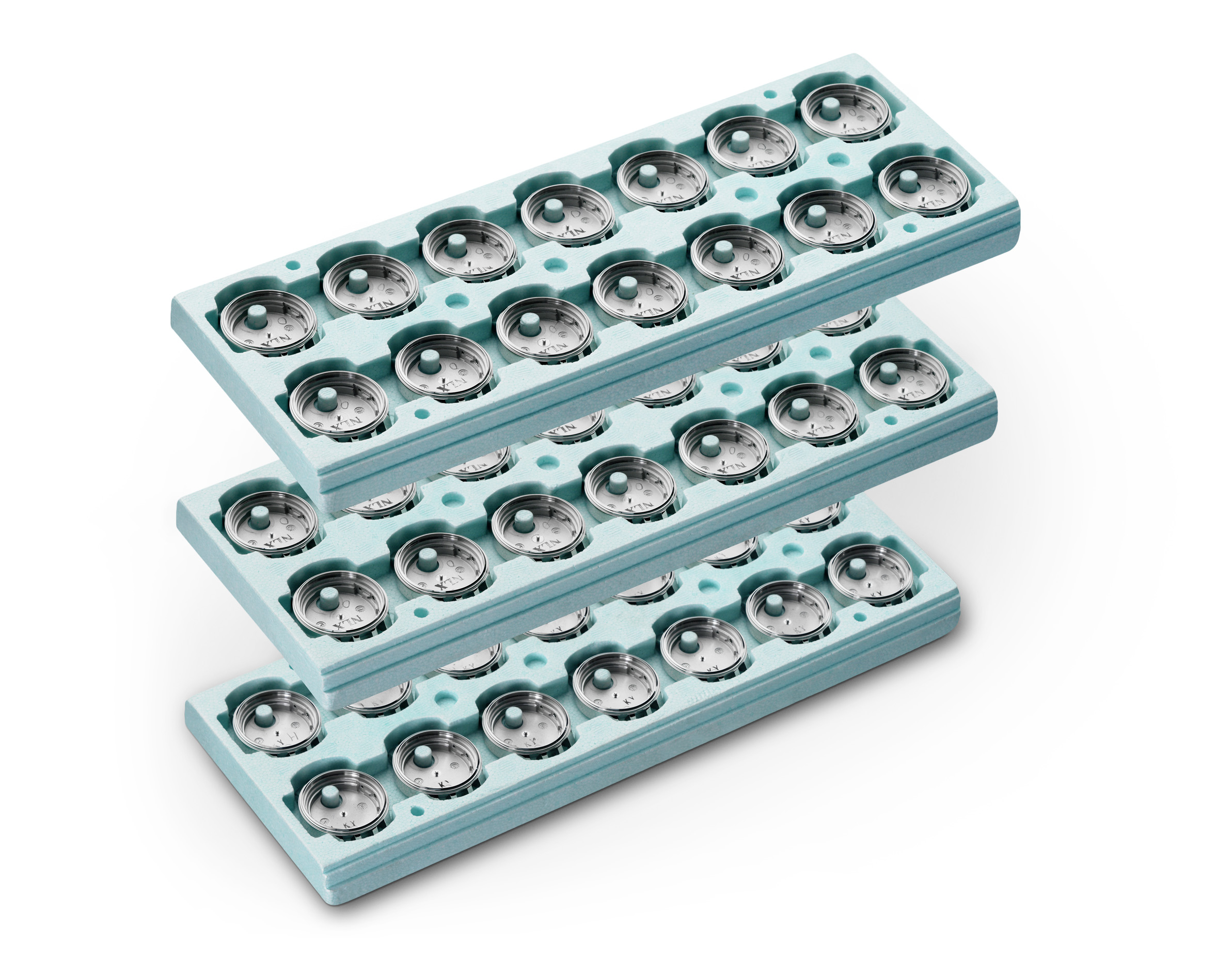

Process optimisation with light, stackable storage pallets

Workpiece holders

Very small parts used in automated, robot-controlled production lines require workpiece holders that are sturdy and accurate to within a tenth of a millimetre. Taracell’s custom-made logistics and storage pallets and delivery units help protect clockwork mechanisms, watch faces and other fine mechanical components during and after the manufacturing process.

Choosing the right starting material can, for example:

- Prevent scratches on implants

- Eliminate electrostatic discharges on electronic components or ammunition

- Use flame-retardant materials according to the UL94 standard

- Implementing crazy ideas

Any more questions?