Effortless mobility

Automotive components made from particle foam

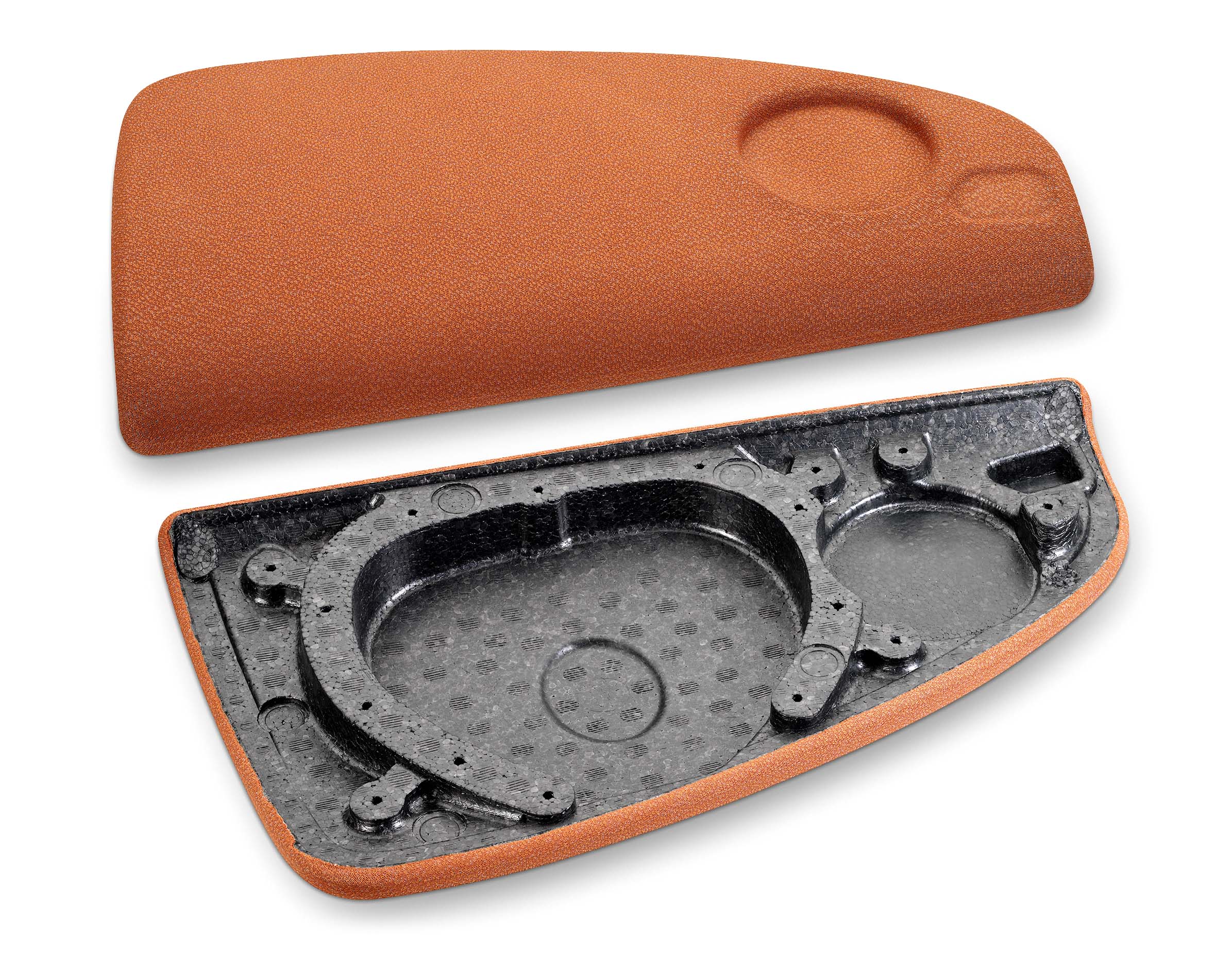

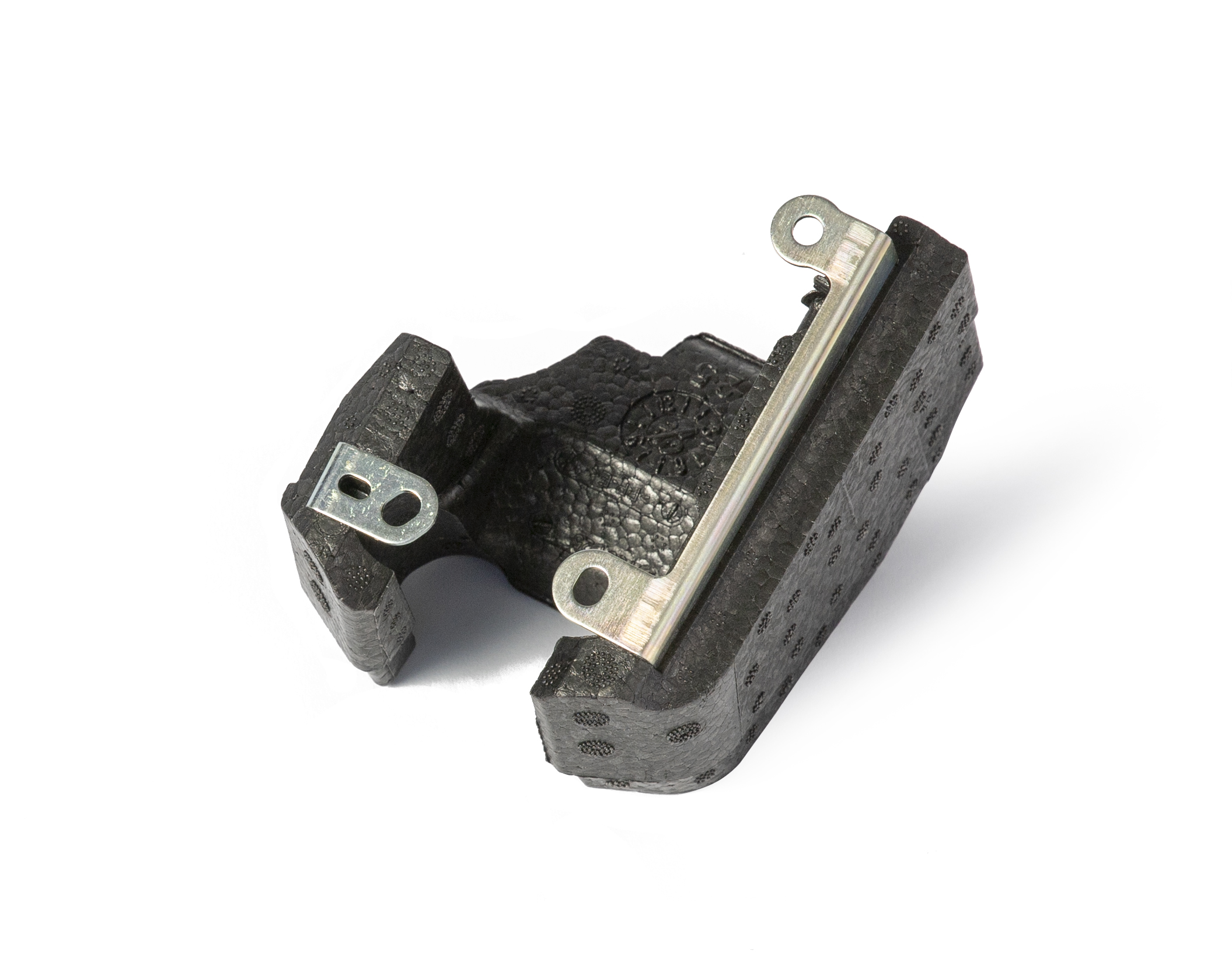

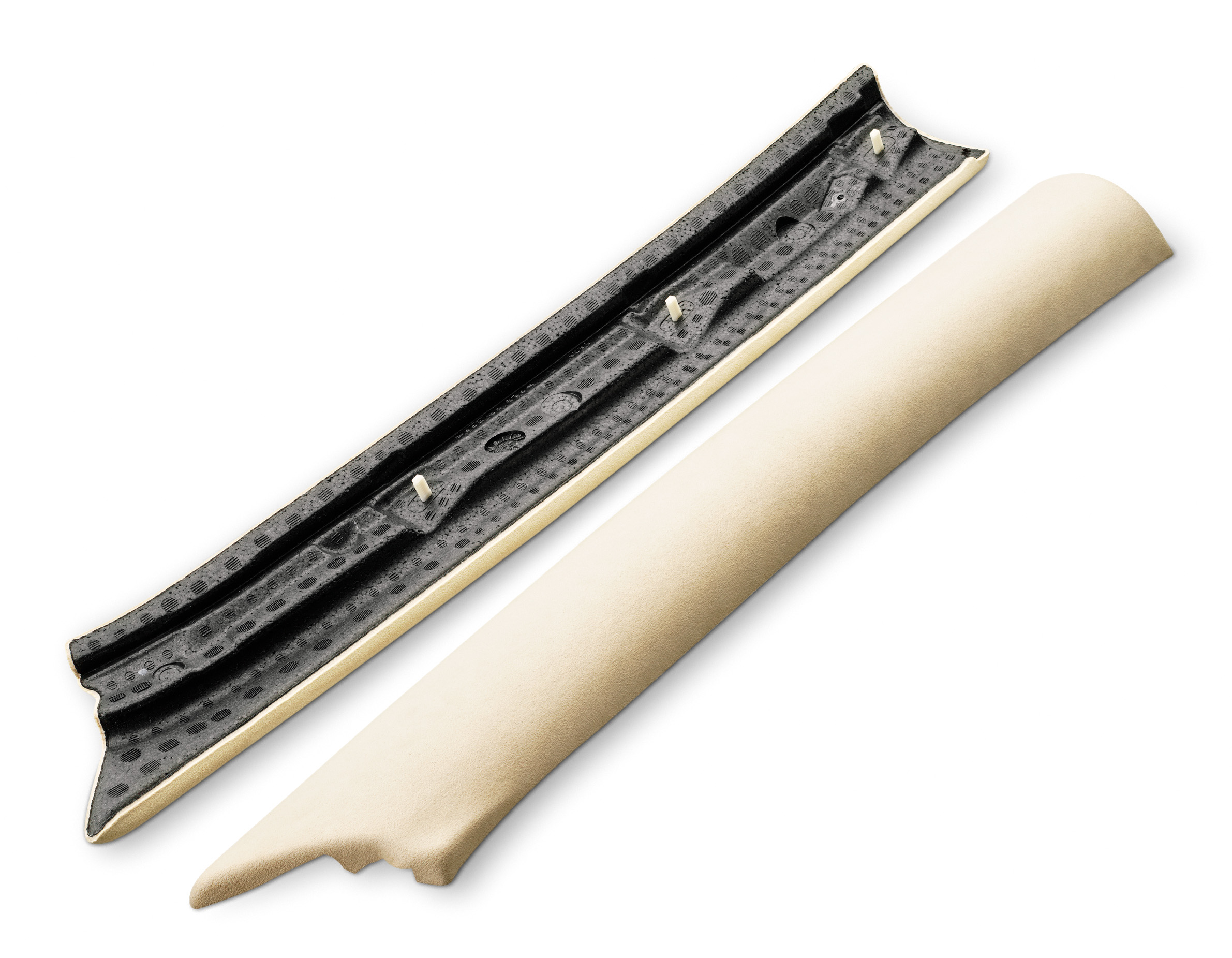

Taracell specialises in the cost-efficient development and serial production of automotive components made from particle foam. Automotive components engineered with back-foamed technology can be covered with various materials (foils, leather, artificial leather, textiles). Because of their excellent impact resilience and thus their high level of cushioning, back-foamed components are primarily used for safety-related interior components. Combined with the low weight of EPP and its excellent acoustic and insulating properties, there are a number of possible applications for automotive engineering.

Do you have any questions?